Ailoys

Deliver results, reduce waste and guide operators in real time - with plug-and-play AI for your existing machines. Ailoys brings the power of AI in the form of a plug-and-play dongle.

3 Core AI Solutions

for Manufacturing Excellence

Ailoys AI helps manufacturers overcome production challenges, optimize efficiency, and reduce errors. Discover how our key solutions transform industrial processes.

Solution #1

Digital Fingerprint

Solution #2

AI-Powered Quality Control

Solution #3

AI-Driven Process Optimization

Digital Fingerprint

AI analyzes sensor data and predicts potential equipment failures before they happen, preventing costly downtime.

- AI detects potential issues in advance

- Prevents unexpected shutdowns

- Maintenance happens only when necessary

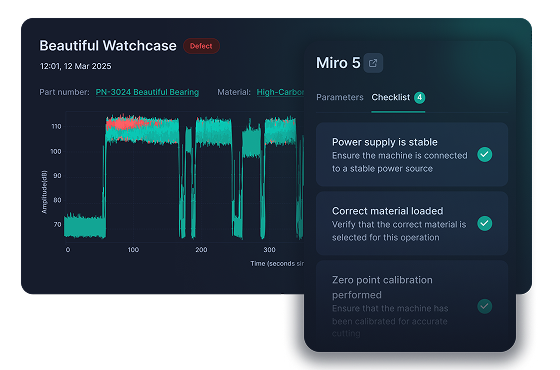

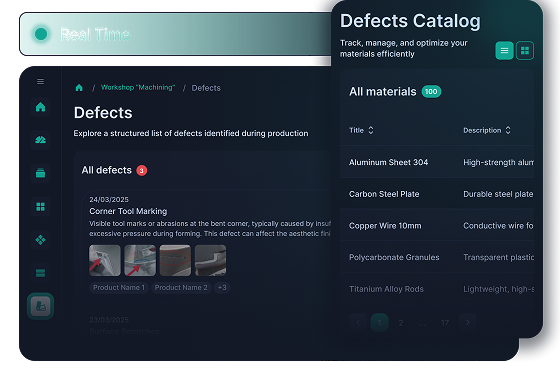

AI-Powered Quality Control

AI inspects products in real time, identifying defects faster than traditional quality control methods.

- Automated real-time product inspection

- Minimized rework and production losses

- Immediate defect reports for improved decision-making

AI-Driven Process Optimization

AI continuously analyzes manufacturing processes and suggests optimal adjustments for maximum efficiency.

- Optimized machine speed and performance

- Reduced energy consumption

- Improved production planning and scheduling

Explore Process-Specific Solutions

What You Can Gain

Ailoys AI-driven solutions optimize manufacturing efficiency, reduce costs, and prevent unexpected downtimes — giving you complete control over your production line.

+30%

Overall Equipment Efficiency

Ailoys AI predicts failures before they happen, minimizing unplanned production halts

+20%

Higher Production Output

Optimize manufacturing operations with AI-driven process automation.

100%

Significant COGS reduction

Gain full visibility of your operations with real-time AI-powered analytics.

-25%

Fewer Defective Products

AI-driven quality control identifies defects in real time, ensuring higher product standards.

How Ailoys AI Transforms Your

Production Process

Ailoys seamlessly connects AI to your production systems, analyzing real-time data and providing actionable insights. Follow these simple steps to unlock maximum efficiency.

01

AI Connects to Your Systems

Seamless integration with your existing production equipment and data sources.

02

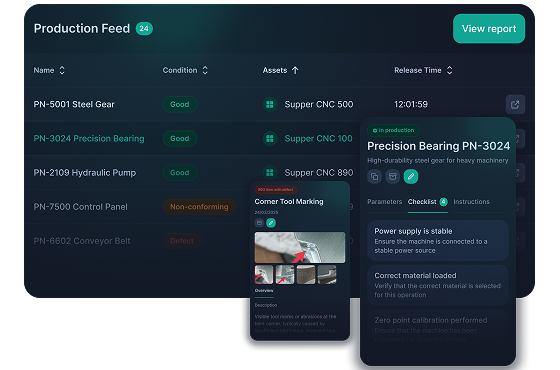

AI Monitors & Analyzes Operations

Ailoys continuously processes real-time production data, detecting inefficiencies and potential issues.

03

AI Recommends Process Improvements

Automated adjustments optimize production speed, quality, and cost efficiency.

04

Get Reports & Take Smart Actions

Easily track performance metrics and implement AI-driven recommendations.

What Makes Ailoys Different

Real Signals, Real Time

We combine edge-mounted sensors with a smart industrial AI that works where production happens — not in the cloud. That means zero lag, no blind spots, and immediate reaction to what the machine is actually doing.

From Monitoring to Action

Most systems report problems after they happen. Ours prevents them. Operators receive clear, step-by-step instructions before the part goes out of spec — or the system self-corrects in real time.

Transparent, Human-Friendly AI

Ailoys doesn’t operate as a black box. It explains what changed, why it matters for the process, and what corrective action is recommended — in operator language.

Works With What You Have

No need for MES integration or controller rewrites. Ailoys connects to existing machines — fast to install, fast to scale, and built for legacy infrastructure.

Sample Use Case

Real-world results powered by Ailoys AI

Based on scenario modeling, not production deployment.

Use Case #1 — CNC

20% Scrap Reduction. 40% Faster Response.

In a high-precision machining setup, undetected tool wear and vibration led to groove inconsistencies. These subtle changes went unnoticed during production and were only detected during final QA checks, resulting in defects and elevated scrap rates.

What Ailoys did

- Detected micro-instabilities in torque and vibration in real time

- Alerted operators before tool degradation crossed critical thresholds

- Suggested speed-feed compensation based on historical optimal cycles

Outcome

- Scrap rate reduced by 20%

- Groove inconsistencies of 10–70 µm avoided

- Operator response time to deviations improved by 40%

Use Case #2 — Wire Drawing

90% Fewer Surface Defects. 30% Faster Throughput.

In a high-voltage EV cable production line, switching to a new copper-aluminum alloy introduced instability into the wire drawing process. The manual setup struggled to handle variations, resulting in inconsistent speeds and frequent surface defects.

What Ailoys did

- Using a Physics AI model, built a digital twin of the stable wire drawing process to detect deviations in real time

- Predicted instability and suggested real-time adjustments

- Enabled operators to intervene before failures occurred

Outcome

- 90% reduction in surface defects

- 30% increase in drawing speed

- 20% improvement in yield, boosting P&L performance

Use Case #3 — Tube Manufacturing: Medical Devices

15% Scrap Reduction. 25% Faster Changeovers.

In a precision tube manufacturing line for medical devices, variations in wall thickness and ovality emerged during high-speed forming. These deviations often developed gradually and remained undetected until destructive testing at the end of the shift, leading to wasted material and rework.

What Ailoys did

- Monitored forming forces and vibration patterns in real time

- Detected early drift in wall thickness before it exceeded tolerance

- Provided operators with speed and alignment adjustments to stabilize the process

Outcome

- Scrap rate reduced by 15%

- Changeover time between tube sizes decreased by 25%

- Maintained wall thickness consistency within ±0.03 mm

Use Case #4 — Additive Manufacturing: Aerospace

35% Faster Build Times. 50% Fewer Post-Processing Corrections.

In a metal additive manufacturing cell for aerospace components, thermal distortion and micro-porosity often led to rejected parts or extensive post-processing. Issues were typically identified only after printing completed, when defects were visible in CT scans or dimensional checks.

What Ailoys did

- Analyzed acoustic emissions and thermal signatures layer-by-layer

- Detected early indicators of porosity and layer misalignment

- Suggested laser power and scan path tweaks to fix deviations on the fly

Outcome

- Build times reduced by 35% through optimized layer parameters

- Post-processing corrections cut by 50%

- First-pass yield increased from 78% to 92%

Built by Engineers. Trusted by Manufacturers.

Ailoys was founded to fix what most smart factory tools miss: real connection to the process. We built a system that senses, predicts, explains — and helps teams act in real time.

Sergei Altynbaev

CEO and Founder

Albert Klein

Co-Founder

Join Us at Industry Events

Meet Ailoys at leading global manufacturing exhibitions. Experience our technology in action and explore how we can help improve your production efficiency.

Sustainable Aero Lab

EXPO & CONVENTION – Formnext

Trusted by Industry Leaders